Recently on a business trip i had 6 hours to spare so I decided to grab a bullet train ticket to the city of Dongguan, Guangzhou to visit a distillation plant/factory which I thought was potentially one of the most promising oud oil producers to have appeared in the recent years.

Bullet Trains in China are just so convenient, comfortable and fast!

There could be hundreds and hundreds of oud distillers.. but what made Yuzhi Agarwood so special that it was worth a detour for me? Because of many reasons!

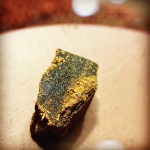

They do CO2 extraction, that is they pull out everything from raw materials, leaving behind fibrous materials, producing a thick brown paste that has swirls of white in it. Essentially a huge pot of oil/oleoresin/resin (brown) interspearsed with streaks of natural “waxes” found in wood fibres. something like smucker’s peanut butter with jelly.

From this Extract, they put it through a high tech fractionation process which separates the waxes and some resins from the oleoresin/oil fraction.

Fractionation set up

Resin.

This is essentially the largest dedicated agarwood extraction/fractionation process in the world right now, able to produce up to 3-5 kilograms of oleoresin/oil daily. That makes over 100kg a month!

Total CO2 Extraction Set up – 3 extraction chambers

Giant Condenser…!

The owner, Jeff Zeng, made the smartest choice ever to do the extraction process on Aquilaria Sinensis. Because I had done extractions in the past before using different methods from CO2 to other gases to diethylethers etc.. on southern materials, i.e. malaccensis, filaria, gyrinops etc, they all give a very hard resin concrete from the process which is not easy to fractionate. Aquilaria Sinensis does not give hard resin, but in basic extraction before fractionation, it gives a thick sticky liquid oleoresin that is easier to work with. Aquilaria Crassna will also give a sticky material, slightly more viscous than sinensis. Basically, Jeff extracts mostly his own Sinensis trees in Guangzhou/Dongguan that he owns, so he can control the cost. He has also developed his own slow innoculation method on 8-9 year old trees using safe “kitchen” ingredients which leaves no trace at all in his agarwood extract, so much so that I could not glean what he used in the GCMS analysis of his oil. The oil/resin formation in his trees are quite good, although not dense, but has clear presence in the rays and laterals.

The scale and extent… I think some day IFF or Firmenich.. or Givaudan.. or Robertet.. or.. some big fragrance/flav company should collaborate with him. I’m way too small to be a collaborator.

With his own source of raw material, still planting trees and rotating plots to infect/innoculate, a successful oil/resin induction method, a huge processing plant, and high tech CO2 regenerator/recovery process, high tech fractionation etc as a full one stop solution, he has been able to provide at wholesale, a price of $16 USD per gram or $16000 USD per kilogram of oud oleoresin oil extract. If you want to see the oil collection you can see it here at :

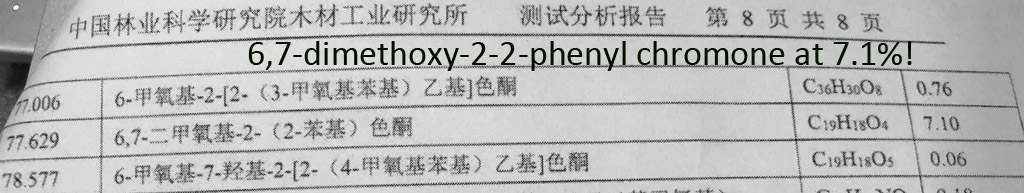

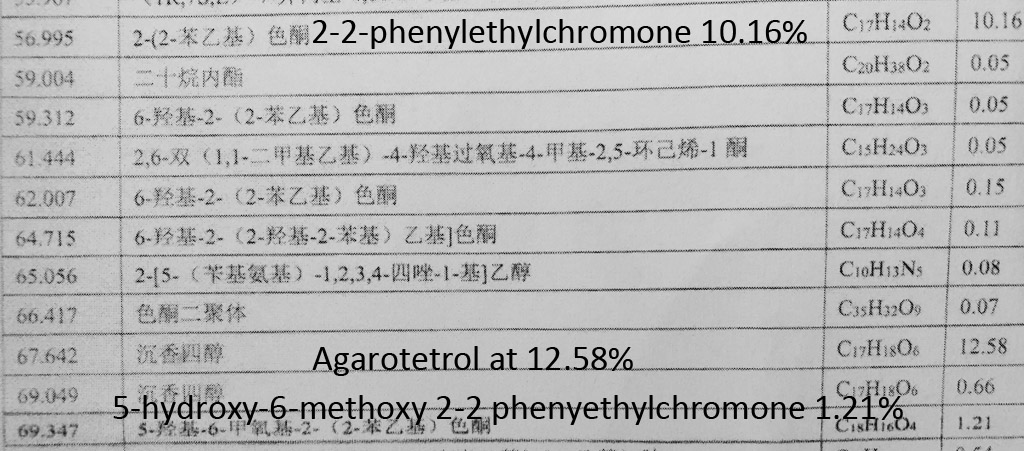

So why is KZ excited? because this oleoresin oil extract tests very well in GCMS, clean and pure, and containing good amounts of aquilaria sinensis actives. It is also tested clean from heavy metals, pesticides etc.

That aside, this oleoresin oil extract smells very good for the price, it is the heart note of sinensis or “northern aloeswoods”, the woody, sweet, vanillic, calming core. Quite like the scent of gently heating quality sinensis or vietnamese woods on a heater.

when applied in tiny amounts and exposed to air/skin contact/sweat, it takes on some “salivary oudy” tones. This profile was only encounted in certain products on the market, i.e. a chinese oud oil procured from Japan, or from some agarwood museum gift shop in China.. or some other online products with so called unofficial “white kyara/kinam” claims. Jeff appears to have other expanded series i.e fermented oud now but when I was there I only got to see Oud 1 and Oud 2.. which are both excellent.

I personally see great potential in this product. In my experiments. I have used this oleoresin oil extract to dilute/cut steam distilled ouds, i.e. 1ml of malinau to 2ml of a.sinensis oleoresin oil, or 1ml of hindi to 4ml of a.sinensis oleoresin oil, gave very good results! longer longevity on skin (due to the thicker/heavier oud oleoresins helping hold down the volatile steam distilled oils), moderation of the ultra heady almost “psychoactive” high notes in steam distilled oils, making them smoother, and also enhancing the mid tones in weight, and depth in drydown. I’m not saying it would work for all steam ouds to good effect, but of the five to seven i had tried at varying dilutions, i.e 1:2 to 1:5.. all were great! What does this mean to the consumer or the oud merchant? Reduced costs, and potentially better performance if you like the profiles. So, if a steam distilled malinau will cost $80 per ml, using a $16/ml extract to dilute it will reduce costs by 66% and yet volatility is only diminished by 25%…. you do the math yourself. Also, because this extract tests very well on GCMS, you are just diluting steam distilled oud compounds with co2 extracted oud compounds. I dont think there can be any better “diluent” or “enhancer” on the market.

As the GCMS results belong to Jeff, I’m not posting everything up here but you can see how promising it is.. agarwood chromones.. easily over 30% content! if you add all the small contributions from other intermediate chromones in the gcms.. i’m sure it will be over 40+% agarwood chromone content..

Long story short, I think Sinensis CO2 is here to stay, it can be put to multiple uses, it has a long term sustainability, and currently appears to be at quite a decent cost. If any of you readers happen to drop by Dongguan, do drop Jeff a text via wechat or facebook to visit and see for youself. note : there is no financial benefit or any sort of these things for me on writing about this, just that I felt i had to share because Jeff is doing something/successfully done I had always wanted to do, except he had done it on a gigantic scale. The other greater potential in future is if he can achieve certain pyrolysis strategies to convert resin back into oil.. i.e. in nature oil becomes resin over time in infection.. whether he can do catalytic cracking or some controlled breakdown, will be the next chemical breakthrough that will raise oud yields to tremendous levels, i.e. 10% resinated wood will give 10% oil yield.. imagine that?!

Anyway.. PLEASE do not write to me on enquiries.. go contact Jeff if you have any questions..i.e. you can find him as Jeff Zeng Oud Oil on facebook. If i happen to come across any other good CO2 fractionators/extractors i’ll update this post.

PS: There may be a possibility of organizing a simple mass order some day if there are sufficient people interested in small samples rather than big volume purchase. It would be at transparent costs (i.e. within usd $16 for 1ml if Jeff isn’t going to hike prices soon) +a small % markup for handling.